Many of our customers who have availed themselves of this service have noticed a remarkable difference in their fuel efficiency after each cleaning.

When the propeller is kept in an ultra-smooth condition (Rubert A or A+) that’s where the real fuel savings and speed can be achieved.

This finish can only be accomplished with in-water polishing of the propeller.

The ‘bottom line’ for the customer depends on the cost of the service deducted from the financial savings resulting from the polish. Provided the job is done properly, the cost of the underwater polish will only be a small proportion of the fuel savings, and therefore the most important factor to be considered by the customer is the quality of the polishing.

Benefits of propeller polishing

The sole purpose of polishing a propeller underwater is to reduce the surface roughness.

Removing marine growth and calcium deposits is giving a super smooth surface which is inhospitable to marine organisms as well as being beneficial to the efficiency of the propeller performance and reducing stress on the propeller shaft and ship’s engines.

High quality and best equipment

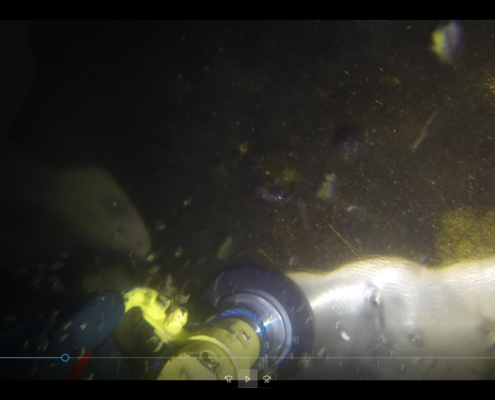

Seatek have constantly improved the standard of our surface finish and we only use the best equipment. Our hydraulic polishing equipment provides a suction force of 100kg to the propeller surface but can be maneuvered over the blade face easily by the diver.

With exceptionally fine abrasives we can achieve a surface finish of 0.5µ Ra